Endurica: Oxidation modelling to reinforce case for retreading

4 Sep 2025

New prediction tools can extend casing life while ensuring safety and performance

Findlay, Ohio – When it comes to building a greener future, the tire industry has a powerful ally in retreading, which extends tire life, reduces waste, and delivers major environmental and economic benefits.

So says Dr. Mahmoud Assaad, senior technical advisor at Endurica, which has developed new tools to help reinforce the case for retreading among tire makers, retreaders and consumers.

Retreading is a “proven sustainability champion,” believes Assaad, noting that the process gives new life to around 18-20 million tires a year, including 15-17 million truck & bus tires and 1-3 million aviation, OTR, consumer tire.

As each retread means fewer raw materials consumed, less manufacturing energy used, and significantly lower CO? emissions, it reduces both the cost and environmental footprint of mobility.

However, the extended-life tires face a “hidden challenge” in the form of rubber oxidation: a gradual breakdown of the molecular structure as oxygen slowly diffuses into rubber, Assaad points out.

This, he said, leads to a deterioration of physical properties, including a loss of elasticity, increased brittleness, reduced flexibility and fatigue resistance.”

“If left unchecked, oxidation can shorten the service life of tire casings making it harder to maximise the value of retreading,” the Endurica technical expert continued in a 22 Aug release.

The critical oxygen absorption level is the point where rubber loses its mechanical integrity depending on the rubber formulation, environmental exposure, and antioxidant content.

When this threshold is exceeded, tires are at risk of accelerated wear along with critical safety issues, such as blowouts and tread separation, according to Assaad.

Endurica has, therefore, developed new modelling capabilities to predict oxidation-related degradation before it becomes critical and set data-driven acceptance criteria for casing reuse.

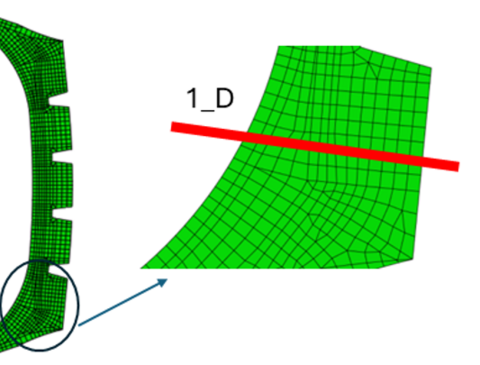

These capabilities encompass 3D or 2D finite element model for detailed casing simulations, as well as 1D analytical/numerical tools for rapid assessments.

For retreading, a ‘numerical oxygen diffusion’ model maps oxygen concentration across the casing surface: calculating the time to reach the critical O? threshold – towards extending casing life, safety and performance.

Oxidation threshold modelling, claims Endurica, can therefore keep tires rolling longer, reduce environmental impact, and strengthen the economics of tire reuse.

Concludes Assaad, these capabilities “push the limits of casing reuse safely by keeping more tires out of landfills, lowering environmental impact, and delivering better economic returns.”