Engel to advance integrated LSR moulding at Expoplast

Schwertberg, Austria – At Expoplast, Engel will use a liquid silicone rubber (LSR) application to show how “flawless interplay” between injection moulding machine, automation, process technology and Industry 4.0 can maximise stability and reproducibility.

Processing of LSR involves challenging requirements in terms of process stability and precision, as well as ensuring maximum cost-effectiveness, Engel said in a release ahead of the trade show taking place 21-24 Nov in Sibiu, Romania.

“This applies in particular to mass-market products such as baby goods and membranes for industrial applications,” said Sergiu Sora, managing director of Engel Injectiem, based in Bucharest.

At Expoplast, Saora said Engel will “clearly demonstrate how high product quality can be achieved at minimal unit cost in LSR processing by means of sophisticated machine technology, automation and process integration.”

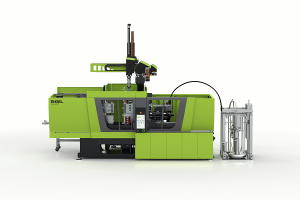

Over the four days of the event, Engel will use a Victory 200H/200L/160 combi injection moulding machine with integrated viper 40 linear robot to produce two-component pressure reservoir membranes used in pressure compensation containers.

In a single stage, the machine will process PBT and LSR simultaneously in a two-component mould. Only the integrated injection process makes it possible to bond thermoplastics and silicone together in stable layers.

The manufacture of the membranes fully exploits the efficiency potential of the tie-bar-less clamping unit of the Victory machine, according to the Austrian machine maker.

Since the bulky mould extends to the edge of the mould mounting platens, it can be installed on a relatively compact 160-tonne machine, said Engel. This, it added, cuts both investment costs and operating expenses.

Automation is another efficiency factor, the company continued: “The linear robot can access the cavities directly from the side, without having to negotiate obstacles, and operate safely there.”

Thirdly, Engal claimed that the “very high” process consistency ensured by the tie-bar-less clamping unit provides a significant contribution to the high overall efficiency.

A patented force divider enables the moving mould mounting platen to follow the mould exactly while clamping force is building up and ensures that the clamping force is evenly distributed across the platen face.

This way, both the outer and inner cavities are kept closed with exactly the same force, which reduces mould wear and raises product quality, according to Engel.

“To manufacture high-tech products of liquid silicone in a cost-effective way, you need burr-free, waste-free, fully automated processing of LSR with no reworking required,” concluded Sora.

This article is only available to subscribers - subscribe today

Subscribe for unlimited access. A subscription to European Rubber Journal includes:

- Every issue of European Rubber Journal (6 issues) including Special Reports & Maps.

- Unlimited access to ERJ articles online

- Daily email newsletter – the latest news direct to your inbox

- Access to the ERJ online archive