Oven to take stress out of relaxation tests

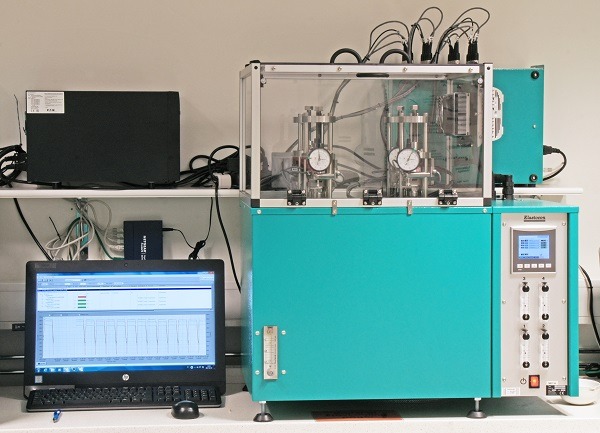

Brämhult, Sweden – Elastocon has introduced a new ageing oven for continuous stress-relaxation tests. The EB 21 LTHTP is said to be the first such oven offering individual temperature control for an oven with programmable cycling temperature.

The unit has four cells with individual control of both the air exchange rate as well as the temperature. Cooling is done with tap water, and to be able to reach standard laboratory temperature the water temperature should not exceed +18°C.

Water consumption is said top be "very low" while maximum temperature is given as 300°C.

This enables automatic relaxation tests according to ISO 3384-B and SAE J2979 where the force measurements is done at standard laboratory temperature, said Elastocon.

Test can be carried out without the need to lift the jigs out of the oven for cooling in the ambient temperature, the company pointed out.

Technicians, it added, can test four different single samples/materials in individual temperature cycling, in the same oven at the same time.

A continuous saved logging point throughout the entire test means less work and more data available after tests are complete, Elastocon also stated.

This article is only available to subscribers - subscribe today

Subscribe for unlimited access. A subscription to European Rubber Journal includes:

- Every issue of European Rubber Journal (6 issues) including Special Reports & Maps.

- Unlimited access to ERJ articles online

- Daily email newsletter – the latest news direct to your inbox

- Access to the ERJ online archive