Respondents to the ERJ Machinery Survey 2018 have highlighted the increasing role of automation within technology-development programmes. (Article published in March/April edition of European Rubber Journal magazine)

London - While the drive to automate every stage of the tire-making has been under way for several years, it is now starting to build real momentum among equipment suppliers.

For a third straight year tire & rubber machinery is undergoing a major change in automation, which will increase in 2018, according to Pelmar Engineering.

This, said the Israel-based supplier, “reflects in almost all process equipment and generates quite a lot of engineering work, which is carried out by Pelmar.

This assessment is backed a clear beneficiary of the trend, Finnish-based plant automation company Cimcorp, which stated: “We feel the market is active and with a good feel for the year ahead.”

Automation, it seems, is an increasing element within every area of tire-making, including heavy-engineering side, such as mixing and calendaring.

Among its latest innovations, for instance, Comerio Ercole has also developed smart-factory dedicated service packages to support and orient customers towards Industry 4.0 systems and connected process/technologies.

Other recent advances at the Italy-based company include virtual reality platforms; integrating MES and sensors for predictive maintenance plan and remote problem-diagnosis and support.

Comerio Ercole added that is now able to manage joint development projects: supplying engineers and technology know-how services to help customers adopt MES packages and ‘smart factory’ solutions.

Also in Italy, Marangoni Tyre Machinery says it has realised a goal of achieving fully automated strip-winding systems. The process covers feeding to the extruder up to the winding on carcass, without any human intervention along the lamination line.

The technology includes a new generation ‘strip-shuttle’ system to feed and transport the laminated rubber-strip along the whole line.

Marangoni has also enhanced some features to increase productivity and flexibility along medium-small production lots of tires. These include extrusion outlet check and control, auto-feeding of calenders and automatic rubber strip delivery to the application point on tire carcass.

The trend to automate extends into mould management, as evidenced by German laser system supplier 4Jet’s development of automated laser cleaning systems.

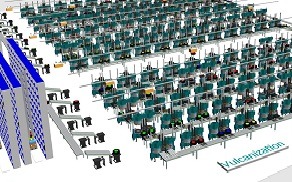

Laser cleaning of vulcanising moulds is widely used in tire manufacturing, and noted 4Jet, the technology is also finding increasing use in the cleaning of moulded rubber goods.

In order to clean moulds in a fully automated process, the mould plates, or entire tire moulds, are cleaned in a stationary system that features a six-axis optical cleaning head. The moulds are positioned on a carrier table and moved in the process chamber.

Depending on tool size and complexity of the shapes, the cleaning process takes several minutes to half an hour. After cleaning is completed, the tool can immediately be put back into production without a need for post-processing.

US company RJS Corp., meanwhile, is introducing an electronic control platform for real-time creel room monitoring, measurement, and control.

The technology controls system air pressures and the resulting tension control output to a user-defined set point through an automated feedback loop, eliminating the need for manual adjustment. It also monitors loose/broken wires, room temperature, and relative humidity conditions.