Nynas opens new lab for rubber process oils

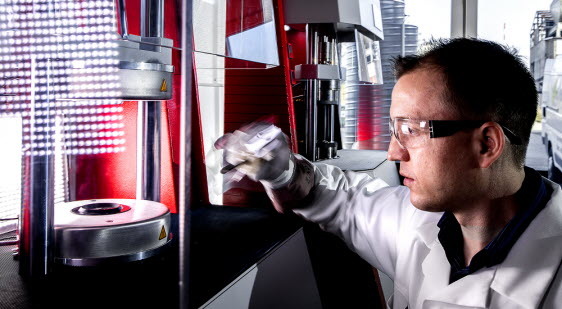

The lab features an intermeshing 1.5 litre rubber mixer and an open mill, as well as instruments for measuring viscosity, curing behaviour, physical and dynamic properties, ageing, abrasion and set.

“Our new in-house rubber compounding and testing laboratory will enable us to gain additional hands-on application and formulation knowledge," said Dr Mika Lahtinen technical manager, Nynas Naphthenics.

These capabilities will help the company to support customers in finding the best oils for their applications by demonstrating the technical value of the process oils, according to Lahtinen.

For example, he said, this can be done by “formulating and fine-tuning rubber compounds, estimating the potential of new materials, identifying optimised processing conditions and in general providing a second opinion on the compounding of rubber.”

Through better evaluating the performance of its oils in rubber, Nynas said it will also improve sales support and accelerate approval processes in the tire, rubber and thermoplastic elastomer industries.

This article is only available to subscribers - subscribe today

Subscribe for unlimited access. A subscription to European Rubber Journal includes:

- Every issue of European Rubber Journal (6 issues) including Special Reports & Maps.

- Unlimited access to ERJ articles online

- Daily email newsletter – the latest news direct to your inbox

- Access to the ERJ online archive