Based on article published in Nov/Dec issue of European Rubber Journal magazine.

Efforts to advance the performance of tire rubber are moving in a new direction, led by Japanese tire makers who have long been to the fore in applying advanced analysis and R&D techniques to materials science.

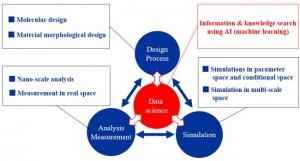

Typifying the latest thinking, Yokohama Rubber Co. Ltd has established a development technology for rubber materials based on ‘materials informatics’. This features the use of simulation technology that emerged from the company’s efforts to optimise the structure of rubber-compounds.

Yokohama’s approach involves the use of data from its research in the design, processing, analysis and measurement of existing rubber materials. It also incorporates information and knowledge exploration using machine learning based on artificial intelligence.

The new programme builds on work started in 2015, through which the company developed a technology that has enabled it to run predictive simulations of the mechanical properties of virtual rubber materials.

The ultimate goal is to “dramatically raise” accuracy and speed in its development of advanced rubber materials, said Yokohama – noting that tire performance is highly affected by the complex morphology of filled rubber materials.

The use of AI to analyse vast amounts of simulation results “makes it possible to derive the morphological design factors critical to achieving the desired performance [and] in a short period of time,” said Yokohama.

Product development, it added, will be further enhanced by new molecular dynamics simulation techniques that make it possible to analyse how various design factors impact mechanical properties.

“Using this new technology to simulate a rubber material could overcome the contradiction of combining superior rolling performance with high wear resistance,” Yokohama commented.

R&D on the road

Having pioneered the study of tire rubber on the molecular scale, Sumitomo Rubber Industries aims to develop tires that respond to changes in road conditions by actively changing the functionality of tread rubber to suit varying road-surface and temperature conditions.

The project is being carried out under Sumitomo’s Smart Tyre Concept roadmap, which also targets the development of new materials that enhance environmental performance throughout the tire-lifecycle – from raw materials and tire production to shipping, usage and even recycling.

Another area of focus for Sumitomo is on countering the degradation of tire performance due to wear and rubber deterioration “to maintain the performance of a tire like brand new for longer.”

This R&D effort includes the development of new materials that enable rubber to control and recover from internal structural deformation and that compensate for functionality that has been lost due to rubber deterioration.

For its part, Bridgestone is also prioritising several technology areas, among them the development of “innovative, tough polymer composites enabling more durable tires while conserving resources.”

This work, it said, will focus on the development of proprietary catalyst and process technologies to convert isoprene into polymers “surpassing” the performance of natural rubber.

Ultra-thin rubber

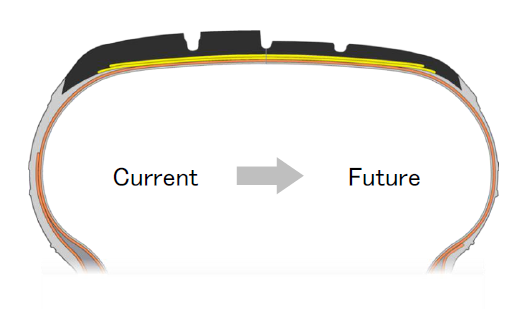

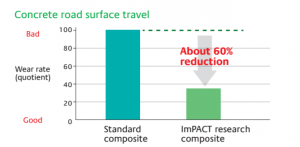

Meanwhile, Bridgestone’s efforts to reduce tire-weight and fuel-consumption, include participating in Japan’s ImPACT (impulsing paradigm change through disruptive technologies) programme. This aims to provide “tough, flexible polymers that achieve both thinness and toughness exceeding conventional limits.”

Through the research, said Bridgestone, it can develop strong material that “exceeds previous limits and create tires that achieve greater resource conservation.”

According to the tire-maker, results so far have shown that the wear rate for running durability of the rubber composite developed through this research was 60% lower than that of a standard composite.