UK firms link to enhance elastomers with nanomaterials

The project with Martin’s Rubber aims to use the Ammanford-based firm’s HDPlas functionalised nanomaterials to deliver advanced aerospace and automotive parts, said a 26 Oct release.

The UK-based companies have been optimising combinations of the nanomaterials, functionalisations and filler loadings to improve the mechanical, electrical and dynamic properties of various elastomers.

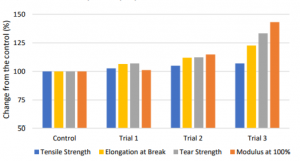

Haydale reported that as filler was substituted with its nanomaterials, modulus and elongation-at-break increased. Tensile and tear strength increased at higher substitution, while density was reduced.

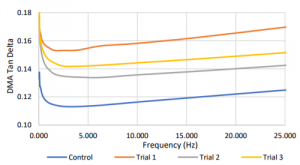

“The array of elastomers produced ranged from resistive to conductive, and the damping characteristics were also improved, as shown through an increase in tan delta,” the company continued.

“The increase in elastomer properties shown through these trials, a range of benefits can be realised: stronger and more lightweight rubber parts, improved part manufacturing and increased electrical and dynamic performance,“ concluded Haydale.

Separately, Haydale recently announced a joint project with Artis and Trelleborg Antivibration Solutions to investigate plasma-functionalisation of rCB (recovered carbon black) from scrap tires.

This article is only available to subscribers - subscribe today

Subscribe for unlimited access. A subscription to European Rubber Journal includes:

- Every issue of European Rubber Journal (6 issues) including Special Reports & Maps.

- Unlimited access to ERJ articles online

- Daily email newsletter – the latest news direct to your inbox

- Access to the ERJ online archive